Overview

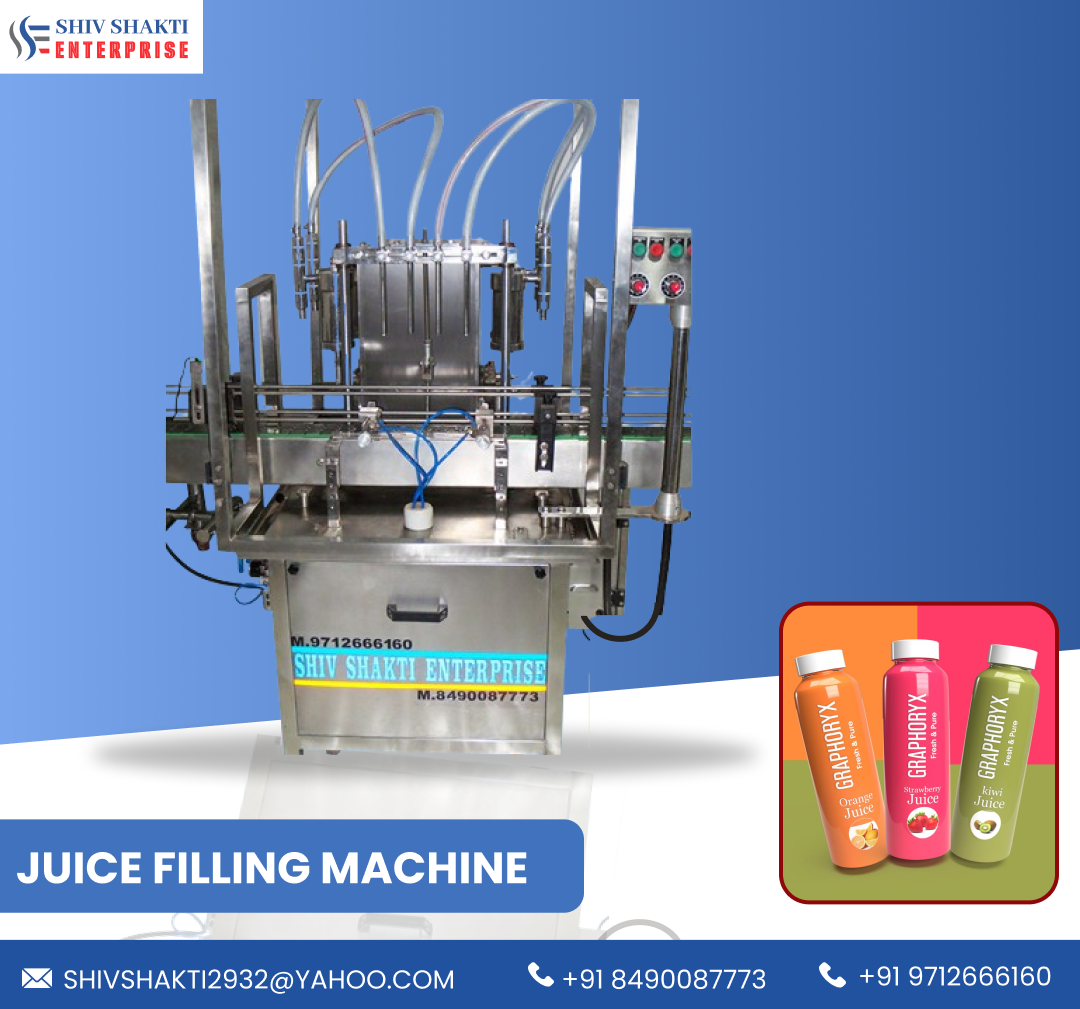

Shiv Shakti Engineering Works, located in Ahmedabad, Gujarat, is a leading manufacturer, supplier, and exporter of high-quality Juice Filling Machines, Liquid Filling Machines, Mineral Water Filling Machines, and Automatic Bottle Filling Machines. We specialize in providing advanced, reliable, and efficient filling solutions for the beverage and bottled water industries. Our machines are designed for high-speed, precise filling of bottles, ensuring minimal wastage and optimal production efficiency.

With years of expertise, Shiv Shakti Engineering Works focuses on delivering top-notch **Bottle Filling Machines** tailored to meet the specific needs of your production line. Our filling machines are crafted with cutting-edge technology, offering features like automatic operation, easy maintenance, and enhanced durability.

We cater to clients globally, ensuring timely delivery and superior customer service. Whether you're in the juice, water, or liquid products sector, we have the perfect filling solution for your business.

Contact us today to discuss your requirements and learn more about our top-of-the-line filling machines. Let us help you enhance your production capabilities and achieve greater efficiency!

Specifications

- Production Speed in Bottle per Minute 30/40/60 up to 300 BPM

- The machine is fully neck-run and infeed is by air conveyor.

- There are only two change parts namely the capper star wheel and infeed star wheel, and resetting the machine to different size of bottle will take only 30 minutes.

- There is no height setting requirement during the changeover.

- The complete R.F.C is enclosed in transparent plastic and stainless steel guard cover without any rubber gaskets. This ensures there is no bacterial growth in the crevices

- The electrical panel is IP 55 grade and has a user-friendly mimic panel. Mimic diagram with red, green, yellow LED indicates machine status, safety indication, and normal operation. Merely by monitoring the LED indications, the operator cans diagnose the fault condition.

- There is a central lubrication system, which supplies all vital components. Also, manual grease points located in easy-to-access centralized grease banks.

- The entire R.F.C machine is constructed in stainless steel above the tabletop